ows-0.25

SSME

SSME-WS-002

| Color: | |

|---|---|

| Size: | |

| Material: | |

| Motor power: | |

| Voltage: | |

| Handling Capacity: | |

| Availability: | |

| Quantity: | |

Place of Origin: | Malaysia |

Brand Name: | SSME |

Certification: | CCS |

Model Number: | OWS-0.1,OWS-0.25;OWS-0.5,OWS-1.0,OWS-2.0 |

inspection standards | IMO MEPC.107(49) |

Application: | treat oil-water mixtures from bilge tanks, oil that hasaccumulated water in any compartment of a ship, and is discharged into the sea. |

Printing | customerized Printing, OEM services |

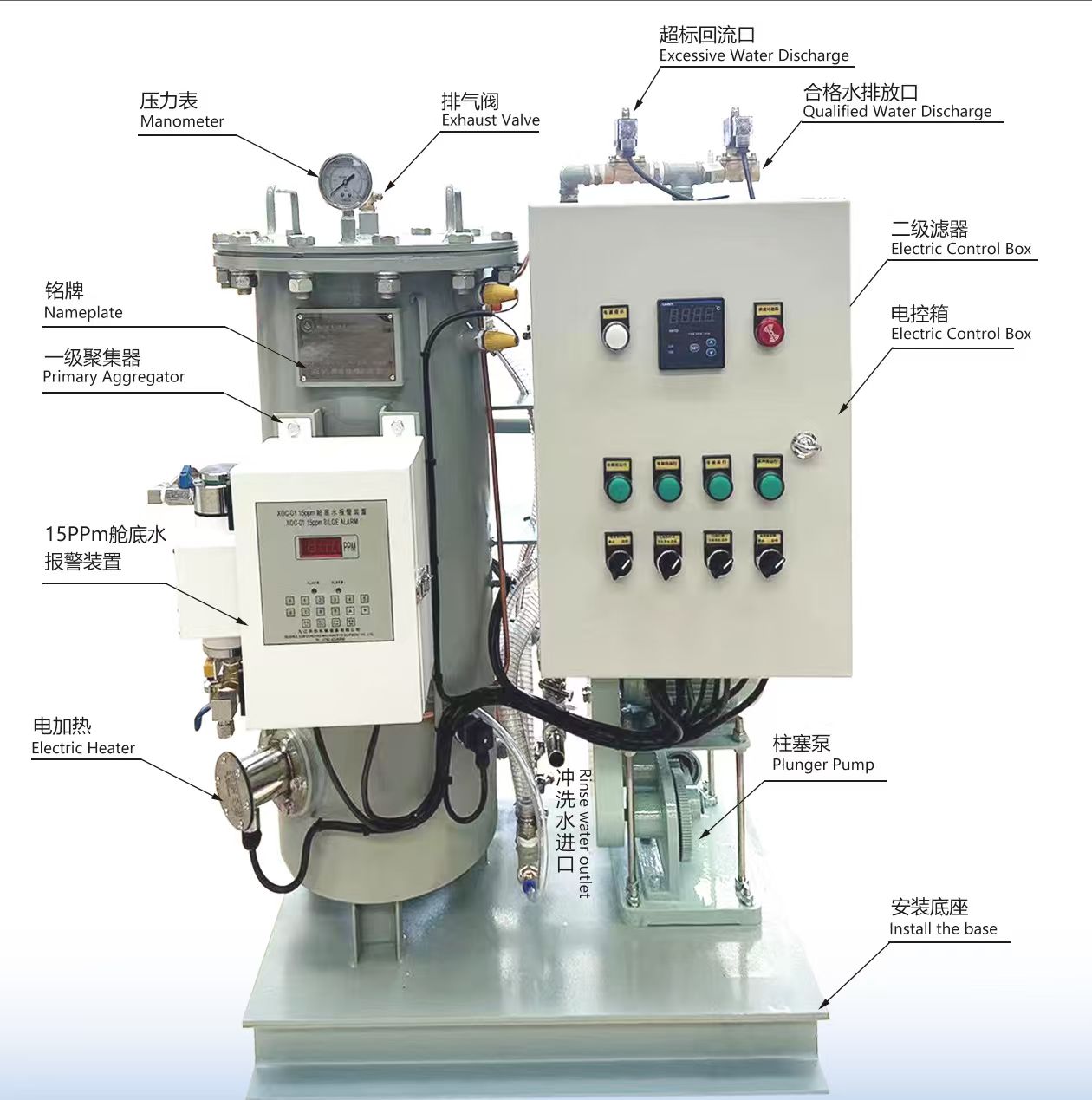

The SSME OWS Series 15ppm Bilge Water Separator is a marine environmental protection device designed to treat oily wastewater from ship bilge tanks. It complies with IMO MEPC.107(49) regulations, ensuring the oil content of discharged water is ≤15ppm (parts per million), meeting international marine pollution prevention standards. It is suitable for all types of ships (cargo ships, oil tankers, fishing boats) and industrial oily wastewater treatment, protecting marine ecosystems.

• No chemical additives: Eliminates the need for emulsion breakers, reducing operation costs and avoiding secondary pollution.

• Low maintenance: Adopts open-pore sponge structure (no ultra-filter membranes), resistant to clogging and easy to clean.

• Multi-certification: Approved by classification societies like CCS, BV, and RMR, ensuring compliance with global marine regulations.

• Three-stage treatment process: Primary aggregator (separates large oil droplets), secondary fiber filter (captures medium oil droplets), and coalescer (removes fine oil droplets), achieving 15ppm discharge standards.

• Oil content monitoring: Equipped with an automatic Oil Content Monitor (OCM), which recirculates water to the collection tank or stops the separator if oil content exceeds 15ppm.

• High processing capacity: Models range from OWS-0.1 (0.1m³/h) to OWS-2.0 (2.0m³/h), adapting to small fishing boats and large oil tankers.

• Corrosion-resistant material: The separator unit and filter are made of 316 stainless steel, resistant to salt spray and oily wastewater corrosion.

• Compact structure: Small footprint, easy to install in limited ship engine rooms.

• Automatic control: Capacitive liquid level sensor controls oil/water discharge valves automatically, reducing manual operation errors.

For ships operating within 12 nautical miles of shore (mandated by the International Convention for the Prevention of Pollution from Ships), the OWS Series ensures bilge water discharge complies with 15ppm standards. It treats wastewater containing fuel oils, residual sludge, and emulsions (from engine rooms), avoiding fines and environmental damage.

In onshore oil refineries or mining enterprises, it treats oily wastewater from production processes (e.g., machine tool cooling water), recycling water and reducing water resource waste. Its low maintenance design is suitable for continuous operation in industrial workshops.

Parameter | Value |

Oil Content Discharge Standard | ≤15ppm |

Compliance | IMO MEPC.107(49) |

Certifications | CCS, BV, RMR |

Processing Capacity | 0.1-2.0m³/h (model-dependent) |

Communication Interface | RS-485 (for OCM data transmission) |

Operating Temperature | 5-50℃ |

Origin | Malaysia |

• Components: Bilge water inlet, primary aggregator, secondary fiber filter, coalescer, OCM, control panel, and backwash outlet.

• Backwash function: Automatically cleans filters when transmembrane differential pressure exceeds 0.2MPa or after 6 months of operation, extending filter life.

• Safety features: Equipped with overpressure protection valves and alarm devices (for high oil content or equipment faults).