| Availability: | |

|---|---|

| Quantity: | |

SSME’s Marine Fiber Optic Gyroscope Compass is a cutting-edge inertial navigation device designed for marine and industrial scenarios where GPS/Beidou signals are unavailable. Comprising three perpendicular fiber optic gyroscopes, three accelerometers, and a modular control unit, it delivers high-precision heading, attitude, and position data for critical operations.

• Autonomous navigation (course error <0.3° within 1 month of GPS failure) for remote marine environments.

• Fuel-saving efficiency (1.5% journey reduction via high heading accuracy) and low power consumption (<25W).

• Minimal maintenance (no regular spare parts replacement) and high reliability (MTBF >30000h).

• High Precision & Stability: Stabilization time of 20 minutes, roll/pitch error ≤0.03°, ensuring accurate navigation for large vessels.

• User-Friendly Operation: Touch display and control unit with intuitive interface, supporting quick startup in sea navigation mode.

• Modular Design: Easy installation and upgrade; compatible with existing ship navigation systems (e.g., Auto Pilot, ECDIS, VDR).

For container ships or bulk carriers traveling in remote oceans (e.g., mid-Atlantic), the compass maintains precise heading without GPS, avoiding course deviations and reducing fuel consumption by 1.5%.

In offshore oil fields, where GPS signals may be blocked by structures or weather, the compass stabilizes drilling platforms and guides supply vessels, ensuring operational safety.

For tunneling or intelligent mining (no GPS access), the compass provides attitude and position data for mining equipment, preventing collisions and improving work efficiency.

Parameter | Value |

Working Latitude Range | 0°~+60° |

Operating Voltage | 12~36V DC |

Ambient Temperature | -40℃~+65℃ |

Ambient Humidity | 92%~98% (non-condensing) |

Data Interface | RS422/NMEA0183 |

Weight | <7kg |

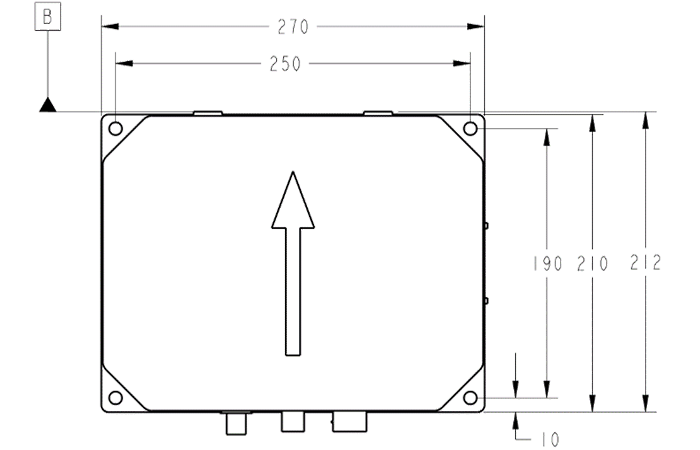

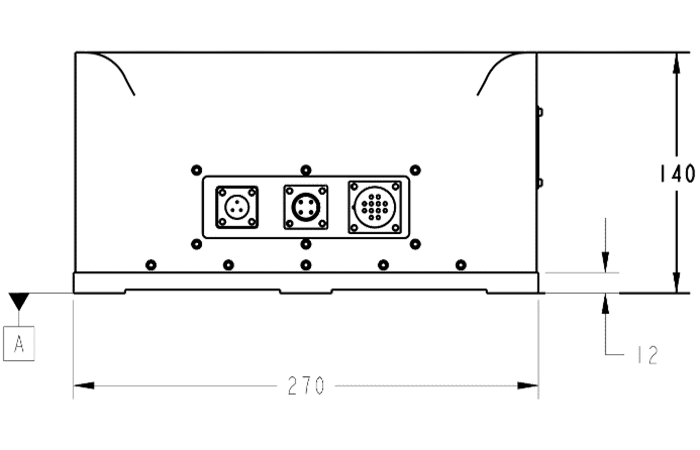

Overall Dimensions | 270*212*140 mm |

Advantage | SSME Fiber Optic Compass | Traditional Electric Compass |

Maintenance Cycle | None required | 1 year |

Power Consumption | <25W | 70~90W |

Weight | <7kg | 17.5~23kg |

Attitude Accuracy | ≤0.03° | Not available |

• Certification: Complies with CCS standards, meeting international marine navigation requirements.

• System Upgrade: Offers two upgrade plans (direct connection to existing distribution boxes or replacement with SSME distribution boxes) for old ships.

• After-Sales: 5-year warranty for fiber optic gyroscopes, with on-site technical support for installation and calibration.

|  |

Fiber Optic Gyroscope Compass Main Bod | Power Supply Unit |

|  |

Distribution uni | Display and Control Unit |

|  |

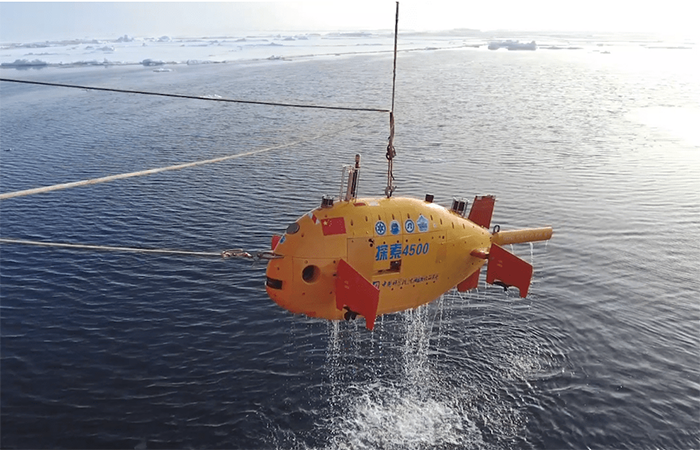

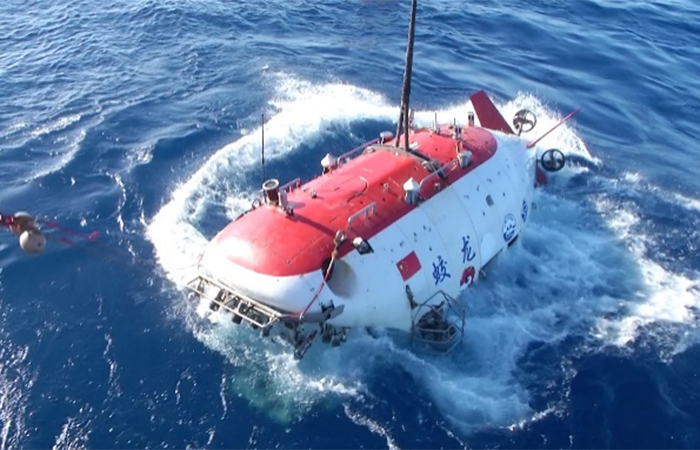

Ocean Voyag | Marine Scientific Research |

|  |

Resource Exploration | Military Field |

Parameter Names | Units | Marine compass |

Stabilization time | min | 20 |

Stabilization point error | deg | ± 0.5 * sec Φ |

Roll and roll error | deg | ≤0.03 |

Working latitude range | ° | 0 ~ + 60 |

Operating voltage | V | 12 ~ 36 |

Power consumption | W | <25 |

Ambient temperature | ℃ | - 40 ~ + 65 |

Ambient humidity | % | 92 ~ 98 |

Data Interface | RS422/NMEA0183 | |

Auxiliary input | GNSS/LOG | |

Weight | <7KG | |

Product size | mm | 270 * 212 * 140 |

MTBF | h | >30000 |

Product certification | CCS |

Fiber Optic Compass VS. Traditional Electric Compass | ||||||

Model | STD-22 | CMZ900 | TG-8000/8500 | Blue Sun-110 | Flashship-19A | Fogcompass Series |

Production unit | Anschutz | Yokogawa | Tokyokeiki | CSSC Navigation | Shanghai Pilot | Zhonghangtianyou |

Product Type | Traditional electric compass | Traditional electric compass | Traditional electric compass | Fiber optic compass | Optical fiber compass | Optical fiber compass |

Maritime stabilization time | No this feature | No this feature | No this feature | 30min | 30min | 20min |

Stabilize point error RMS | ±0.1° secΦ | ±0.25° secΦ | ±0.3° secΦ | ±0.1° secΦ | ±0.22° secΦ | ±0.17° secΦ |

Attitude accuracy | no | no | no | 0.05 ° or less | 0.07 ° or less | 0.03 ° or less |

Dimensions in mm | Φ 411 x 429 | 420 * 420 * 502 | 360 * 340 * 438 | 280 * 203 * 187 | 138 * 113 * 89 | 270 * 212 * 140 |

Weight | 17.5 kg | 23kg | 23kg | 11kg | 3kg | 7kg |

Power consumption | 80w | 90w | 70w | 20w | 15w | 25w |

Maintenance cycle | 1 year | 1 year | 1 year | No maintenance required | No maintenance required | No maintenance required |

Gyro ball warranty period | 1 year | 1 year | One year | - | - | - |

Gyro ball replacement cycle | 3 to 5 years | 3 to 5 years | 3 to 5 years | - | - | - |

Fiber optic gyroscope warranty period | - | - | - | 5 years | 5 years | 5 years |

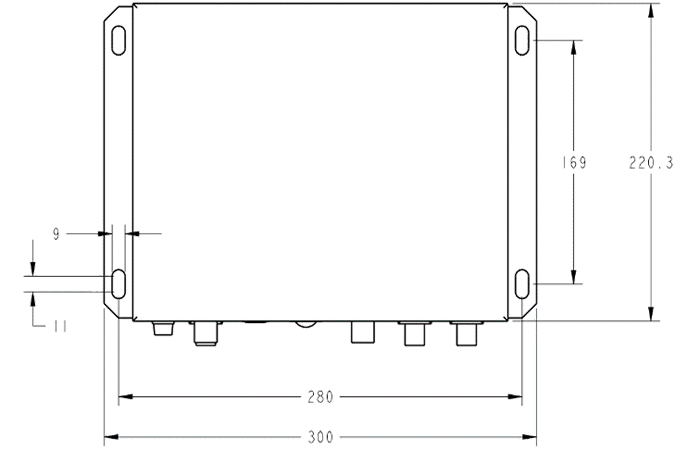

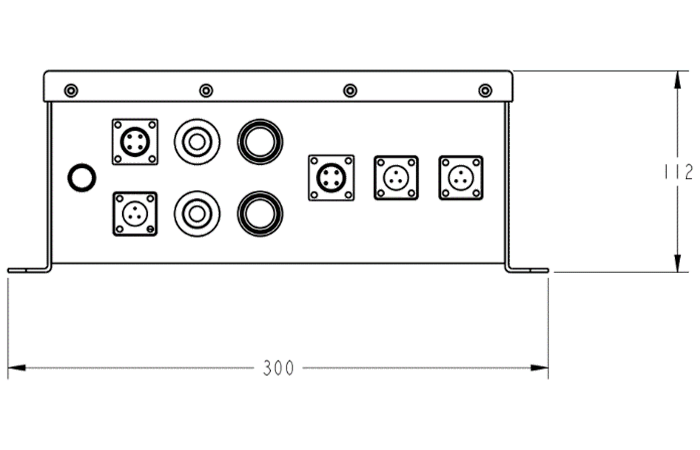

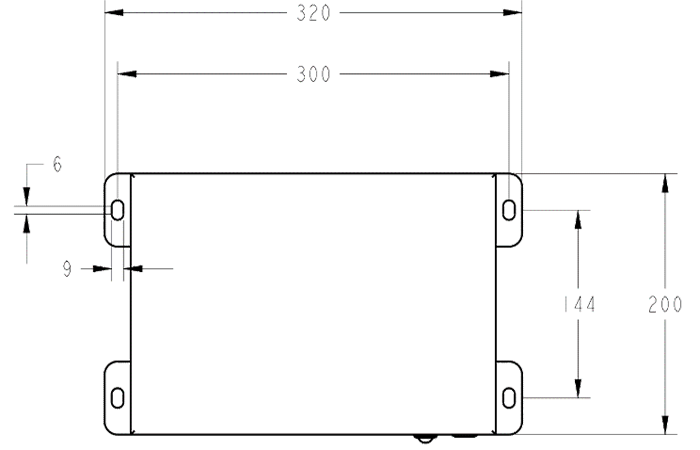

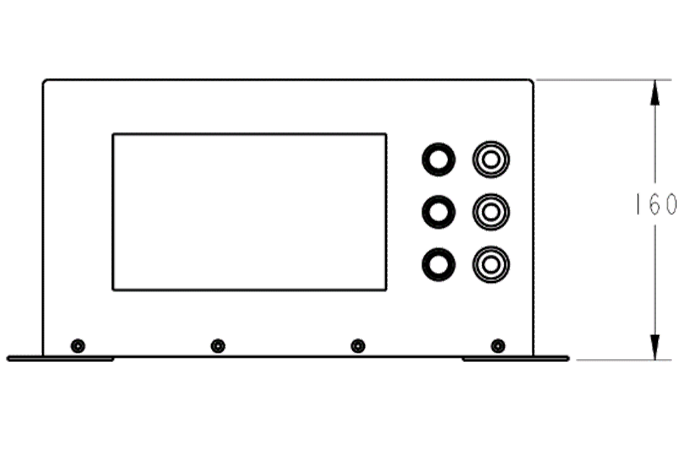

Equipment dimensions and specifications

|  |

Main Dimensions of The Compass Body Diagram | |

|  |

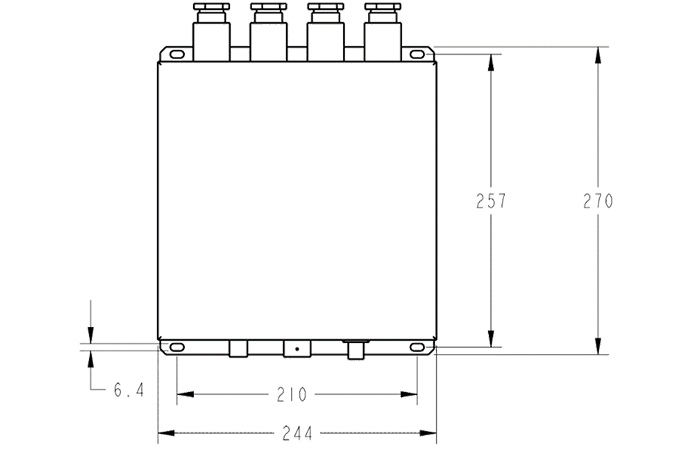

| Power Supply Unit Size Diagram | |

|  |

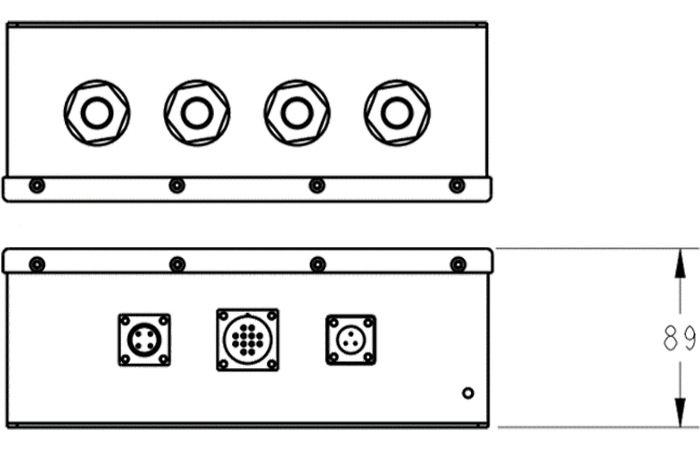

Distribution Unit | |

|  |

Display and Control Unit | |

Partial introduction to installation schemes

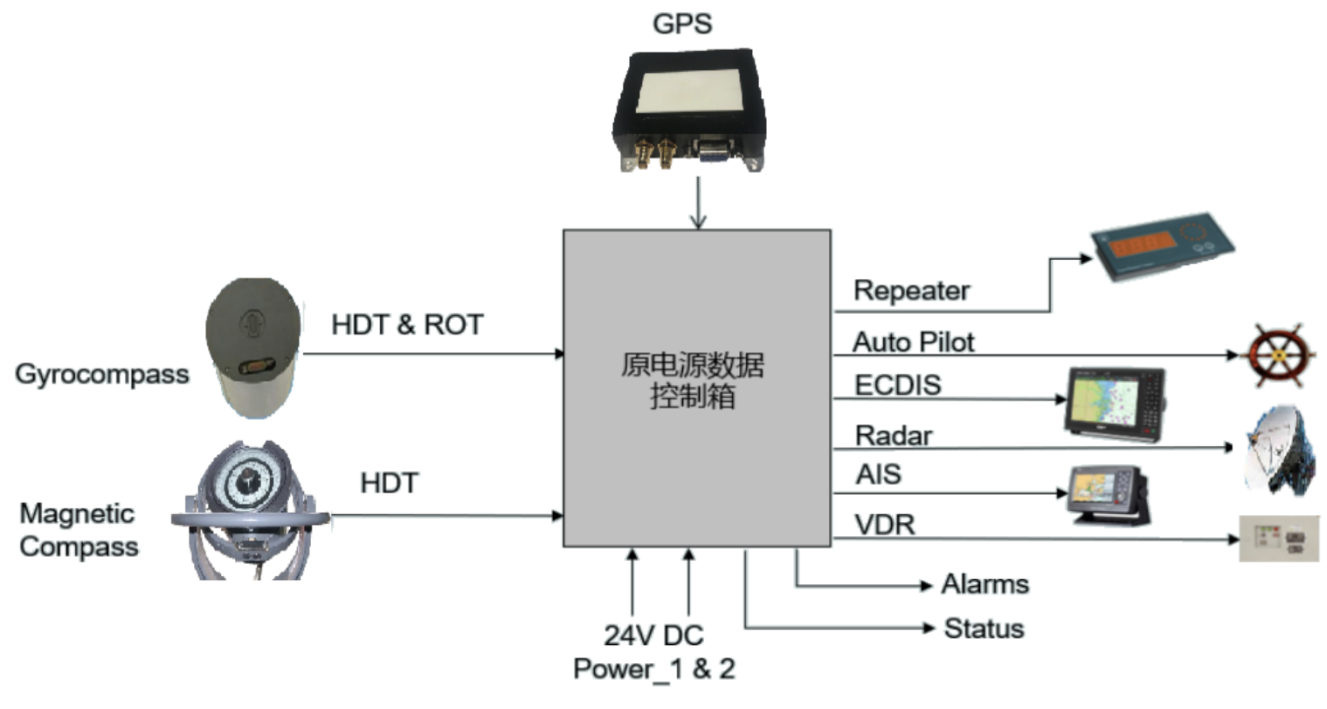

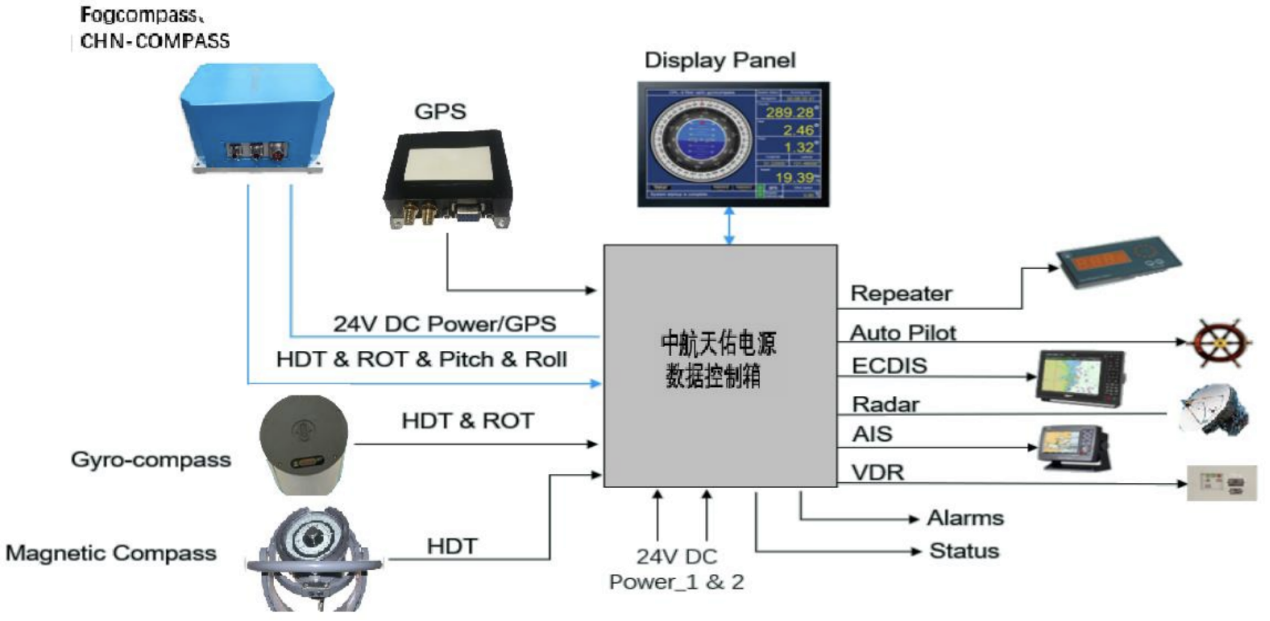

The original system structure of the ship navigation system

System Upgrade Plan A

If the original data distribution box supports Fogcompass/ CHN-COMPASS series fiber optic compass signals, the Fogcompass/ CHNCOMPASS series fiber optic compass can be directly connected to the original data distribution box and provide effective signals to other devices, and the original gyro compass can be used as a backup compass.

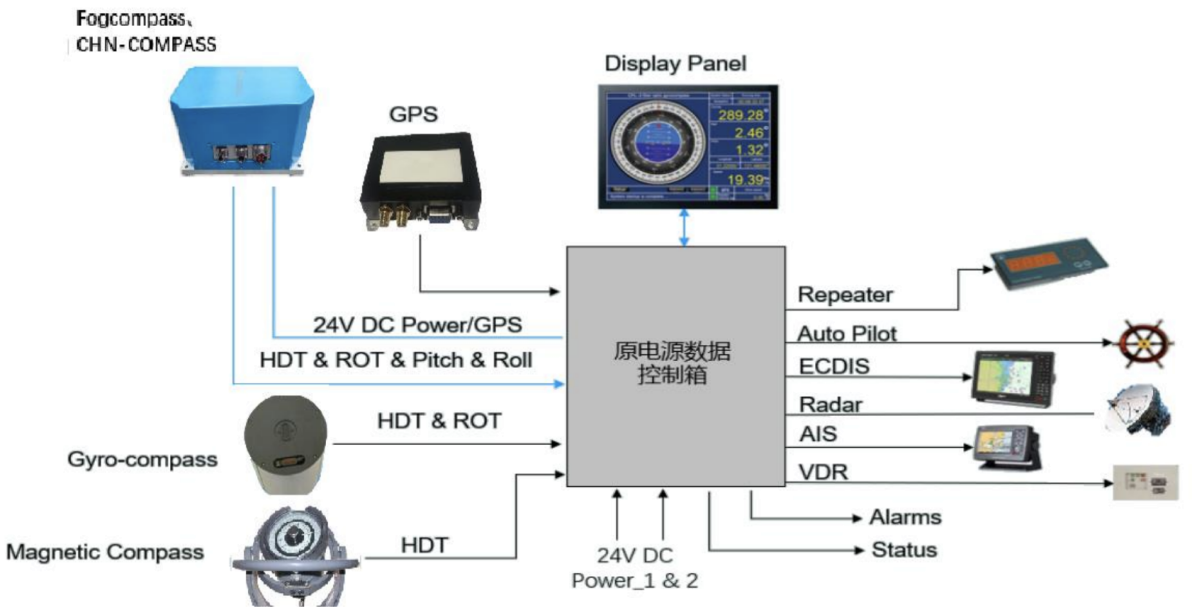

System Upgrade Option B

If the original data distribution box does not support Fogcompass/ CHN-COMPASS fiber compass signals, replace the original data distribution box with the Fogcompass/ CHN-COMPASS data distribution box. The optical fiber compass and other devices are connected to the Fogcompass/ CHN-COMPASS data distribution box and provide effective signals to other devices, and the original gyro-compass can be used as a backup compass.

Critical equipment for gyro production and inertial navigation testing

The error of inertial devices is the main source of error affecting the navigation accuracy of inertial systems. Since inertial instruments are directly attached to mining equipment, they are exposed to harsh angular motion and strong vibration environments, which can cause dynamic errors. If a pure inertial navigation system is used to provide navigation information for mining equipment, over long periods of operation, the equipment navigation information provided by the inertial navigation system will accumulate large errors, reducing the credibility of the navigation information. This requires the use of high-precision inertial sensitive devices to meet the accuracy requirements of the system. However, relying solely on improving instrument accuracy to provide system performance is not the best approach and the cost is unacceptable. If efforts are made on the physical characteristics of inertial instruments and the dynamic model of the inertial navigation system, and the error model of inertial instruments caused by motion is identified through auxiliary means and hidden constraints and then compensated, the navigation accuracy of the inertial navigation system can be significantly improved by an order of magnitude, which has been verified.

(1) Production equipment

|  |

Optical Fiber Coating Machin | OTDR Optical Time Domain Reflectometer |

|  |

Extinction Ratio Teste | Integrated Spectrometer |

|  |

Optical Power Mete | Polarization-Maintaining Fiber Splicer |

(2) Test equipment

|  |

3-Axis Temperature-Controlled High-Precision Turntabl | Marble Horizontal Countertop |