Views: 0 Author: Site Editor Publish Time: 2026-02-05 Origin: Site

Understanding what is true about a self-contained breathing apparatus matters because lives depend on it. In fireground and IDLH environments, breathable air disappears first, long before flames cause harm. Smoke, heat, and toxic gases overwhelm spaces in seconds, making human senses unreliable. This reality explains why Firefighting Equipment must go beyond basic protection and actively sustain life. A self-contained breathing apparatus is not optional gear or emergency backup. It is a purpose-built life-support system that allows firefighters to operate, rescue, and survive when the atmosphere itself becomes the greatest threat.

A Self-contained Breathing Apparatus delivers clean air from a cylinder carried by the user. It does not rely on surrounding air conditions. This independence is the most fundamental truth about SCBA. When oxygen drops or toxins rise, the system continues to function. Firefighters breathe safely even when visibility is zero. This capability defines SCBA as mission-critical Firefighting Equipment. In real operations, independence allows crews to advance, search, and operate without delay or retreat, even in rapidly changing fire conditions.

IDLH environments are immediately dangerous to life or health. Fires create these conditions quickly and unpredictably. Oxygen levels fall while toxic gases increase. A Self-contained Breathing Apparatus is engineered for these realities. Its design assumes the surrounding air cannot be trusted at any moment. Unlike air-purifying respirators, SCBA does not filter harmful air. It replaces it completely. This truth explains why SCBA is mandatory Firefighting Equipment for interior operations where survival depends on controlled breathing.

Modern SCBA systems operate using positive pressure. Air pressure inside the facepiece stays higher than outside air. This prevents contaminants from leaking inward during movement or exertion. Fireground activity makes perfect seals impossible to guarantee. Positive pressure compensates for that reality. This principle is required for firefighting use because it maintains protection even under stress. The reliability of positive-pressure design reinforces why SCBA remains trusted Firefighting Equipment across global fire services.

Fire smoke is a complex and rapidly changing mixture of gases and particles. Many of its most dangerous components are invisible and odorless, making human senses unreliable. SCBA protection works by fully isolating the respiratory system, ensuring firefighters inhale controlled air regardless of surrounding combustion byproducts.

| Hazard Category | Substance or Factor | Typical Fireground Concentration* | Unit | Health Impact | SCBA Protection Mechanism | Operational Notes |

|---|---|---|---|---|---|---|

| Asphyxiant gas | Carbon monoxide (CO) | 1,000–10,000 | ppm | Prevents oxygen delivery to blood; rapid loss of consciousness | Complete exclusion via supplied breathing air | CO is odorless and cannot be detected by smell |

| Chemical asphyxiant | Hydrogen cyanide (HCN) | 50–300 | ppm | Disrupts cellular respiration; often fatal in enclosed fires | Full respiratory isolation | Common in modern synthetic material fires |

| Irritant gases | Hydrogen chloride (HCl) | 30–100 | ppm | Severe airway irritation and lung damage | Prevented from inhalation by facepiece seal | Generated from burning PVC and plastics |

| Toxic nitrogen oxides | NO₂ / NOx | 10–50 | ppm | Delayed lung injury and inflammation | Blocked by positive-pressure system | Effects may appear hours after exposure |

| Particulate matter | Fine soot (PM₂.₅ / PM₁₀) | > 1,000 | µg/m³ | Deep lung penetration; long-term cancer risk | Eliminated by sealed breathing system | Overhaul phase has high particulate risk |

| Oxygen displacement | Reduced O₂ levels | < 17 | % (v/v) | Causes dizziness, confusion, collapse | Independent air supply maintains safe O₂ | Common in confined or ventilation-limited fires |

| Thermal byproducts | Superheated gases | > 150 | °C | Burns to airway and lung tissue | Cool, regulated air delivery | Heat damage occurs before flame contact |

| Combined exposure | Mixed toxic atmosphere | Variable | — | Synergistic, accelerated toxicity | Continuous clean air delivery | Multiple hazards act simultaneously |

| Sensory deception | Low visibility / no odor | — | — | Prevents hazard recognition by senses | Removes reliance on human perception | Critical during overhaul and hidden fires |

| Operational phase | Active fire & overhaul | — | — | Exposure continues after flame knockdown | SCBA required beyond visible fire | Overhaul is a leading exposure phase |

Tip:Overhaul operations often present equal or greater toxic exposure than active fire attack. Maintaining SCBA use until air monitoring confirms safety helps prevent delayed inhalation injuries linked to combustion byproducts.

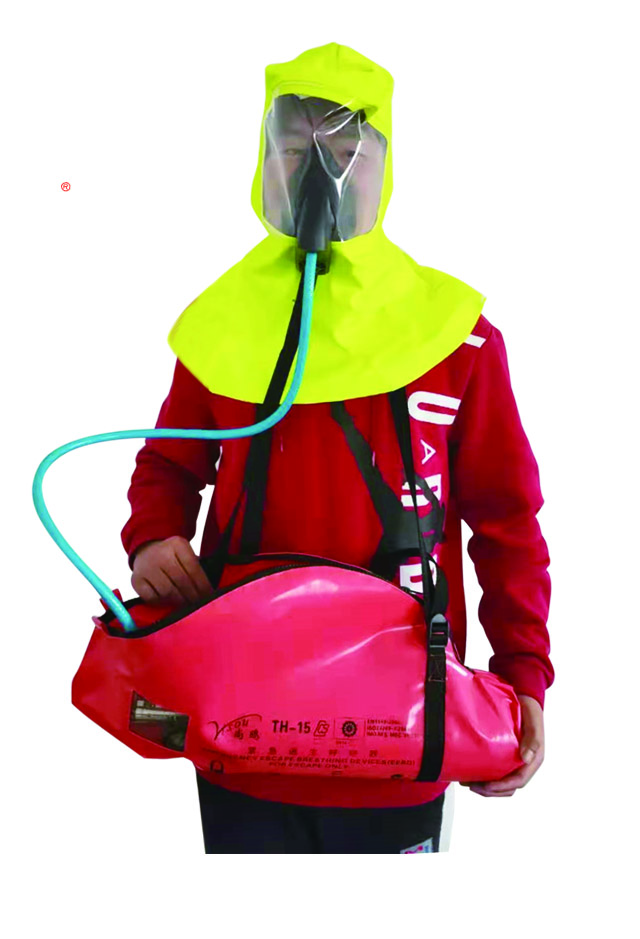

SCBA functions as part of a complete protective system. It integrates with helmets, turnout coats, pants, and protective hoods. The facepiece seals with surrounding PPE to prevent exposure gaps. The harness aligns with structural gear for balance and mobility. Firefighting Equipment must work together under pressure. SCBA anchors that system by protecting breathing, which is always the top survival priority in hostile environments.

Interior firefighting requires confidence and commitment. Crews must move forward despite limited visibility and rising heat. A Self-contained Breathing Apparatus enables that confidence. Firefighters can search rooms, advance hose lines, and remove victims without fear of immediate air failure. This capability directly supports rescue success. Without SCBA, interior firefighting would not be possible. This truth highlights why SCBA remains the backbone of Firefighting Equipment in structural response.

The air cylinder stores compressed, breathable air. It serves as the primary lifeline of the Self-contained Breathing Apparatus. Cylinders are built for high pressure and durability under extreme conditions. They supply air long enough for planned operations when managed correctly. Pressure gauges and warning systems provide constant awareness. Firefighting Equipment depends on predictability. The air cylinder transforms invisible air into a measurable and manageable survival resource.

Air stored at high pressure cannot be breathed directly. Regulators reduce pressure in stages and deliver air smoothly to the user. The system responds to breathing demand rather than exertion level. This controlled delivery supports calm and efficient respiration during intense activity. In Firefighting Equipment design, regulators ensure both safety and efficiency. They allow firefighters to focus on the mission instead of managing airflow manually.

The facepiece creates a sealed environment around the face. It protects the eyes, nose, and mouth together. Materials resist heat, impact, and chemical exposure. The secure seal prevents smoke and gases from entering while allowing clear vision. Communication systems often integrate directly into the mask. This component connects the firefighter to the SCBA system. Without a reliable seal, respiratory protection fails, making proper fit essential.

Open-circuit SCBA systems are engineered for reliability under extreme firefighting conditions. Their airflow path is direct and predictable, supplying fresh compressed air with each breath while safely exhausting exhaled gases. This straightforward design supports consistent performance during heat exposure, high exertion, and low-visibility operations.

| System Aspect | Technical Detail | Typical Specification | Unit | Operational Application | Key Considerations |

|---|---|---|---|---|---|

| Airflow principle | Single-pass, open-circuit flow | Inhale from cylinder, exhale to atmosphere | — | Ensures each breath uses uncontaminated air | No air recycling simplifies system design |

| Breathing gas | Compressed atmospheric air | Grade D breathing air | — | Safe respiration in IDLH environments | Air quality must be regularly verified |

| Cylinder pressure | High-pressure air storage | 2,216 / 4,500 | psi | Supports extended interior operations | Higher pressure requires certified cylinders |

| First-stage regulation | Pressure reduction stage | ~80–125 | psi | Stabilizes airflow from cylinder | Protects downstream components |

| Second-stage regulation | Demand-based airflow | Near ambient pressure | psi | Matches air delivery to breathing rate | Reduces air waste under exertion |

| Exhalation path | One-way exhaust valve | Direct vent to atmosphere | — | Prevents CO₂ buildup in facepiece | Valve must remain unobstructed |

| System response | Pressure-demand operation | Positive-pressure maintained | — | Prevents inward leakage of contaminants | Essential for firefighting safety |

| Thermal tolerance | Component heat resistance | Tested to NFPA 1981 standards | — | Reliable performance in fire conditions | Regular inspection required |

| Moisture handling | Condensation management | Drainage via exhaust valves | — | Maintains mask clarity and comfort | Cold environments increase condensation |

| Maintenance complexity | System architecture | Fewer moving parts | — | Improves reliability and field serviceability | Scheduled checks still mandatory |

TipFor fire departments, open-circuit SCBA performance depends heavily on regulator condition and exhaust valve integrity. Regular functional checks before deployment help ensure clean airflow and consistent positive pressure during high-exertion interior operations.

Air duration depends on cylinder size, pressure, and work rate. Firefighters plan tasks around known air limits. This planning truth supports safe operations and crew coordination. Teams monitor air levels, communicate status, and exit before reserves run low. Firefighting Equipment must support teamwork and timing. SCBA alarms and displays enable this coordination and reduce the risk of sudden air depletion during interior operations.

Fire services prioritize durability, simplicity, and proven performance. Open-circuit SCBA delivers these qualities consistently. Maintenance remains straightforward and predictable. Training remains consistent across departments and shifts. These factors matter at scale. Firefighting Equipment must support large teams under pressure. Open-circuit SCBA continues to meet operational needs while maintaining high safety margins.

PASS devices monitor firefighter movement continuously. If movement stops, alarms activate automatically. This feature helps locate firefighters who may be trapped or incapacitated. Integrated PASS systems function without user input. Accountability becomes built into the equipment itself. In modern Firefighting Equipment, this automatic alert capability supports rapid response and improves survival during low-visibility incidents.

Low-air alarms warn firefighters as air supply decreases. Heads-up displays show air status inside the facepiece. Firefighters no longer guess or stop to check gauges. Real-time feedback supports better decisions under stress. A Self-contained Breathing Apparatus communicates constantly with the user. This communication reduces panic and supports controlled exits when air levels approach reserve limits.

Universal air connections allow emergency air transfer between SCBA units. This feature supports firefighter rescue scenarios during critical moments. One unit can supply another temporarily when needed. Firefighting Equipment must support teamwork during worst-case situations. Air sharing systems extend survival time and reinforce the collective nature of fireground safety.

SCBA performance follows strict regulatory standards. NFPA and NIOSH define testing, durability, and safety requirements. These standards ensure consistent performance across manufacturers. Fire departments trust certified equipment because performance is verified before use. This regulatory framework protects firefighters regardless of brand or model. Firefighting Equipment standards create confidence long before deployment.

In SCBA systems, air quality is just as critical as air supply. Even when equipment performs correctly, contaminated breathing air can silently compromise protection. Grade D breathing air standards establish a verified safety baseline for firefighting and other IDLH operations.

| Category | Technical Parameter | Grade D Standard Limit | Unit | Practical Application | Key Considerations |

|---|---|---|---|---|---|

| Oxygen content | O₂ volume concentration | 19.5 – 23.5 | % (v/v) | Maintains normal respiration and tissue oxygenation | Below 19.5% increases hypoxia risk |

| Carbon monoxide | Maximum CO concentration | ≤ 10 | ppm | Prevents acute poisoning and hemoglobin binding | Often caused by compressor overheating |

| Carbon dioxide | Maximum CO₂ concentration | ≤ 1,000 | ppm | Avoids respiratory acidosis and breathing stress | Rapid buildup indicates filtration failure |

| Total particulates | Solid or liquid particles | ≤ 5 | mg/m³ | Protects lungs from irritation and deposition | Includes rust, dust, and oil aerosols |

| Hydrocarbon vapors | Oil mist or vapor | ≤ 5 | mg/m³ | Prevents inhalation-related lung injury | Requires effective oil separation systems |

| Odor and taste | Sensory requirement | No noticeable odor or taste | — | Provides quick anomaly detection | Sensory checks cannot replace testing |

| Air source | Compressed air origin | Dedicated breathing air compressor | — | Prevents industrial contamination | Never mix with plant air systems |

| Filtration system | Multi-stage filtration | Moisture + oil + activated carbon | — | Removes water vapor, oil, and odors | Filters must be replaced on schedule |

| Testing frequency | Air quality analysis | Every 3–6 months minimum | Time interval | Ensures continuous compliance | High usage requires shorter intervals |

| Documentation | Test and maintenance records | Traceable and auditable | — | Supports compliance and accountability | Retain records for long-term review |

Tip:For departments with frequent responses or intensive training cycles, breathing air testing should align with SCBA maintenance schedules. Treating air quality as part of Firefighting Equipment management helps detect compressor issues early and reduces long-term health risks.

Standards create shared expectations across departments. Firefighters trained in one location can operate SCBA elsewhere with confidence. Controls feel familiar and alarms behave consistently. This reliability supports mutual aid operations and large-scale incidents. Firefighting Equipment must function across jurisdictions. SCBA standards make this interoperability possible and improve safety during complex responses.

This article shows that a self-contained breathing apparatus is essential life-support Firefighting Equipment, not optional gear. It delivers independent, clean air, maintains positive pressure, and protects firefighters in IDLH environments filled with smoke and toxic gases. SCBA enables interior attack, rescue, and overhaul with confidence and control. Reliable components, safety systems, and standards ensure consistent performance across operations. Safe Sail Marine Equipment Sdn Bhd. provides dependable SCBA solutions designed for durability, compliance, and real-world use, helping organizations enhance firefighter safety, reduce risk, and maintain operational readiness in demanding environments.

A: A Self-contained Breathing Apparatus provides independent air and is essential Firefighting Equipment in IDLH environments.

A: Firefighting Equipment like SCBA protects breathing when smoke and toxic gases make air unsafe.

A: It supplies compressed clean air and maintains positive pressure as certified Firefighting Equipment.

A: A Self-contained Breathing Apparatus is required during interior fire attack and overhaul operations.

A: As Firefighting Equipment, a Self-contained Breathing Apparatus ensures safe breathing and mobility.

A: Costs vary, but Firefighting Equipment investment focuses on safety, durability, and compliance.